Titanium alloy TA1 tube can be used i

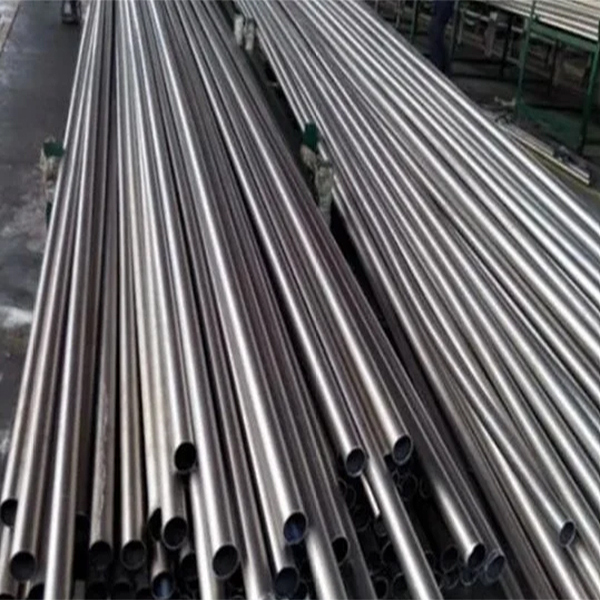

Titanium Alloy TA1 Tube,It is made of titanium alloy, which can be divided into three types according to the structure. (1 Aluminum and tin are added to titanium. Aluminum, chromium, molybdenum, vanadium and other alloying elements are added to titanium. 3 Titanium with aluminum and vanadium and other elements.)They have high mechanical properties, excellent stamping properties, and can be welded in various forms, welding joint strength can reach 90% of the strength of the matrix metal, and good machinability. Titanium tube has high corrosion resistance to chloride, sulfide and ammonia. The corrosion resistance of titanium in seawater is higher than that of aluminum alloy, stainless steel and nickel base alloy. Titanium also has strong water impact resistance.

Titanium Alloy TA1 Tube, The Relevant Standard

GB/T 3620.1-2016 Titanium and titanium alloy grades and chemical composition

GB/T 3624-2010 Titanium and titanium alloy tube standard

Titanium and titanium alloy tubes for heat exchangers and condensers

TA1, TA2 and TA3 are industrial pure titanium, which have high mechanical properties, excellent stamping properties, and can be welded in various forms. The welded joint strength can reach 90% of the strength of the matrix metal, and the cutting performance is good. Titanium tube has high corrosion resistance to chloride, sulfide and ammonia. The corrosion resistance of titanium in seawater is higher than that of aluminum alloy, stainless steel and nickel base alloy. Titanium also has strong water impact resistance.

Used in the manufacture of condenser tubes in polluted seawater, water with high suspended solids content, and at high flow rates.

Titanium Alloy TA1 Tube, Classification

According to the histological

1. aluminum and tin elements are added to titanium.

2. alloy elements such as aluminum, chromium, molybdenum and vanadium are added to titanium.

3. aluminum and vanadium are added to titanium.

Titanium alloy has high strength and low density, good mechanical properties, good toughness and corrosion resistance. In addition: titanium alloy process performance is poor, difficult cutting. In hot processing, it is very easy to absorb impurities such as hydrogen, oxygen, nitrogen and carbon. There are poor wear resistance, complex production process.

Divided by mixed elements

An alloy based on titanium with other elements added. Industrial production of titanium began in 1948. The needs of the development of aviation industry make the titanium industry develop at an average annual growth rate of about 8%. The annual output of titanium alloy processing materials has reached more than 40,000 tons, nearly 30 kinds of titanium alloy. The most widely used titanium alloys are Ti-6Al-4V(TC4), Ti-5Al-2.5Sn (TA7) and industrial pure titanium (TA1, TA2 and TA3).

According to utility cent

Titanium alloy can be divided into heat resistant alloy, high strength alloy, corrosion resistant alloy (ti-molybdenum, ti-Palladium alloy, etc.), low temperature alloy and special function alloy (ti-iron hydrogen storage material and ti-nickel memory alloy), etc. The composition and properties of typical alloys are shown in the table.

Titanium Alloy TA1 Tube, Use

Titanium Alloy TA1 Tube,Mainly used for the production of aircraft engine compressor parts, followed by rockets, missiles and high-speed aircraft structural parts. By the mid-1960s, titanium and its alloys had been used in general industry to make electrodes for electrolysis industry, condensers for power stations, heaters for oil refining and seawater desalination, and pollution control devices. Titanium and its alloys have become a kind of corrosion resistant structural materials. In addition, it is also used to produce hydrogen storage materials and shape memory alloys.

China began to study titanium and titanium alloys in 1956. In the middle of 1960s, titanium material was industrialized and developed into TB2 alloy.

Chemical Composition

| Grade | N | C | H | Fe | THE | Al | IN | Well | Mo | In | Of | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation(%) |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal | 240 | 138 | twenty four |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal | 345 | 275 | 20 |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal | 450 | 380 | 18 |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | 550 | 483 | 15 | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal | 895 | 828 | 10 |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal | 345 | 275 | 20 |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal | 620 | 70 | 15 |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 02-0.4 | 0.6-0.9 | Bal | 438 | 345 | 18 |

| Type | We can also supply TB3, TB6, TC4, TC6, TC11, TC17,TC18 according to your requirements. | |||||||||||||

| Standard | ASTM B348, ASTM F67, ASTM F136, ISO5832-2, ISO5832-3, AMS 4928, AMS 4930, ASTM F1295, ASTM F1713, MIL-T-9047 | |||||||||||||

| Application | Metallurgy, electronics, medical, chemical, petroleum, pharmaceutical, aerospace, etc. | |||||||||||||

Product Display