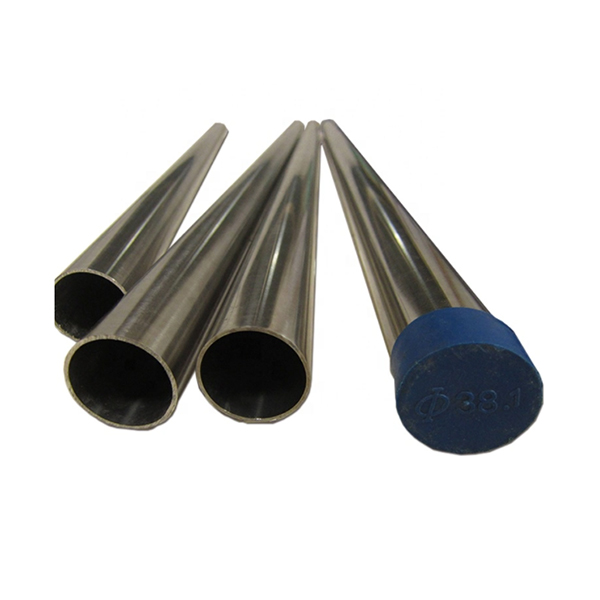

Hot Rolled Seamless Steel Tube

Hot Rolled Seamless Steel Tube, Hot rolling is relative to cold rolling, cold rolling is rolling below the recrystallization temperature, and hot rolling is rolling above the recrystallization temperature.

Hot Rolled Seamless Steel Tube, Advantages

It can destroy the casting structure of steel ingot, refine the grain size of steel, and eliminate the defects of microstructure, so that the steel structure is compacted and the mechanical properties are improved. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent. Bubbles, cracks and looseness formed during casting can also be welded under high temperature and pressure.

Classification

Hot Rolled Seamless Steel Tube, It is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipe.

Cold rolled (dial) seamless steel pipe in addition to general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipe, also includes carbon thin-walled steel pipe, alloy thin-walled steel pipe, stainless steel pipe, special-shaped steel pipe. The outer diameter of hot rolled seamless pipe is generally greater than 32mm and the wall thickness is 2.5-75mm. The outer diameter of cold rolled seamless steel pipe can reach 6mm and the wall thickness can reach 0.25mm. The outer diameter of thin-walled pipe can reach 5mm and the wall thickness is less than 0.25mm.

General seamless steel pipe: it is made of 10, 20, 30, 35, 45 and other high-quality carbon bonded steel 16Mn, 5MnV and other low alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot rolled or cold rolled. 10, 20 and other low carbon steel manufacturing seamless pipe is mainly used for fluid pipeline. 45, 40Cr and other medium carbon steel made of seamless pipe to manufacture mechanical parts, such as cars, tractors stressed parts. The general use of seamless steel pipe to ensure the strength and flattening test. Hot rolled steel pipes are delivered in hot rolled or heat treated condition. Cold rolled delivery is heat - treated.

Allowable deviation of normalized outer diameter

D1 ±1.5%, minimum ± 0.75mm

D2 plus or minus 1.0%. Minimum + / - 0.50 mm

D3 + / - 0.75%. Minimum + / - 0.30 mm

D4 + / - 0.50%. Minimum + / - 0.10 mm

Steel tube weight calculation formula

[(outer diameter - wall thickness)* wall thickness]x0.02466=kg/ m (weight per meter)

Hot Rolled Seamless Steel Tuben, Functional Purposes

1. The construction category is: under the pipeline transportation is more, building extraction of groundwater, boiler hot water transportation.

2. Mechanical processing, bearing sleeve, processing machinery accessories, etc.

3. Electrical: gas transmission, water power generation fluid pipeline.

4. Wind power plant antistatic pipe, etc.

Specification

| Product name | Stainless steel pipe/tube |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Brand | 201/202/304/304L/316/316L/ 321/309S/310S/410/420/430 |

| Certificate | BV, ISO, CE, SGS etc |

| Type | Seamless & welded |

| Outter Diameter (OD) | 3-1220mm |

| Thickness | 0.5-50mm |

| Length | 6000mm 5800mm 12000mm or Customized |

| Technique | Cold Drawn or Hot Drawn |

| Surface | 2B, No.1, No.4, HL, BA, 8K etc |

| Application | Industry,chemical,electricity,machinery,architecture,decoration,etc. |

| Packing | Standard export sea-worthy packing |

| Delivery Time | 7-15 Working Days after Deposit |

| TradeTerms | FOB, CFR, CIF, EXW |

| Payment Terms | 30%T/T,L/C |

Surface Treatment

| Surface | Definition | Application |

| No.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe etc. |

| No.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction etc. |

| No.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment etc. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils etc. |

| BA (No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction etc. |

| Mirror (No.8) | Shinning like a mirror | Building construction, decoration etc. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction etc. |

Chemical Composition

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | |||||

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - | |||||

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - | |||||

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - | |||||

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - | |||||

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - | |||||

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - | |||||

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - | |||||

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | ||||||

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0- | |||||

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 - | |||||

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - | |||||

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - | |||||

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - | |||||

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 | |||||

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | |||||

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | |||||

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - | |||||

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - | |||||

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - | |||||

| Product Name | Material | Standard | Size(mm) | Application | |||||||||

| Low temperature tube | 16MnDG 10MnDG 09DG 09Mn2VDG 06Ni3MoDG ASTM A333 |

GB/T18984- 2003 ASTM A333 |

OD: 25mm~508mm WT:3mm~100mm |

Apply to - 45 ºC ~ 195 ºC low temperature pressure vessel and low temperature heat exchanger pipe | |||||||||

| High-pressure boiler tube | 20G ASTMA106B ASTMA210A ST45.8-III |

GB5310-1995 ASTM SA106 ASTM SA210 DIN17175-79 |

OD:8-1240* WT:1-200 |

Suitable for manufacturing high pressure boiler tube, header, steam pipe, etc | |||||||||

| Petroleum cracking tube | 10 20 |

GB9948-2006 | OD: 8-630* WT:1-60 |

Used in oil refinery furnace tube, heat exchanger tube | |||||||||

| Low medium pressure boiler tube | 10# 20# 16Mn,Q345 |

GB3087-2008 | OD:8-1240* WT:1-200 |

Suitable for manufacturing various structure of low and medium pressure boiler and locomotive boiler | |||||||||

| General structure of the tube |

10#,20#,45#,27SiMn ASTM A53A,B 16Mn,Q345 |

GB/T8162- 2008 GB/T17396- 1998 ASTM A53 |

OD:8-1240* WT:1-200 |

Apply to the general structure, engineering support, mechanical processing, etc | |||||||||

| Oil casing | J55,K55,N80,L80 C90,C95,P110 |

API SPEC 5CT ISO11960 |

OD:60-508* WT:4.24-16.13 |

Used for extraction of oil or gas in oil Wells casing, used in oil and gas well sidewall | |||||||||

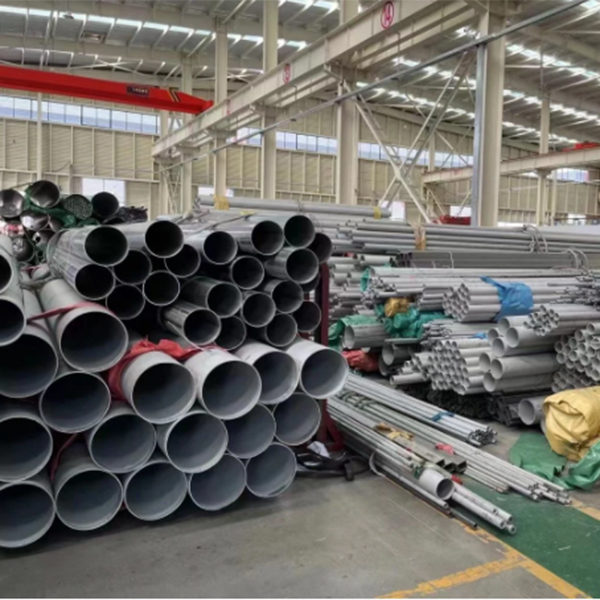

Product Display