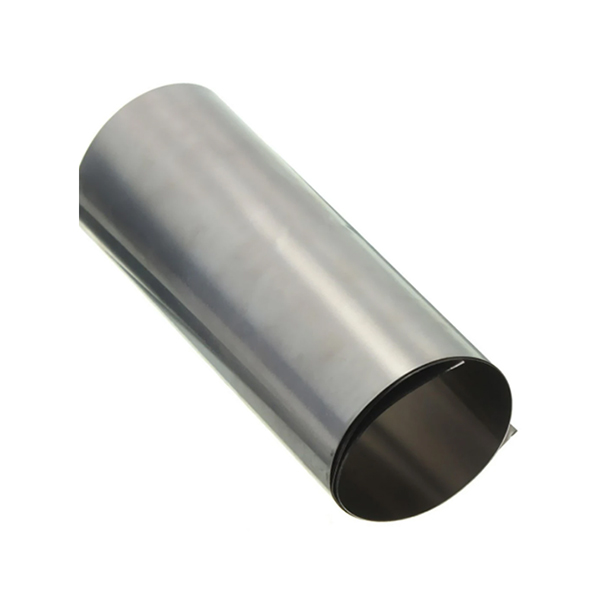

TC2 Titanium Alloy Aheet Plate

TC2 Titanium Alloy Aheet Plate,An alloy based on titanium with other elements added. There are two kinds of homogenous crystals in titanium: α titanium with dense hexagonal structure is below 882℃, and β titanium with body center cube is above 882℃.

Technical requirements:

1. The chemical composition of titanium and titanium alloy plate shall comply with the provisions of GB/T 3620.

2. In the case of reinspection, the allowable deviation of chemical composition shall comply with the provisions of GB/T 3620.

a. the allowable deviation of the thickness of the plate should comply with the provisions of Table 1.

b. the allowable deviation of plate width and length should comply with the provisions of Table 2.

c. the corners of the plate should be cut into right angles as far as possible. The deviation should not exceed the length and width of the sheet

TC2 Titanium Alloy Aheet Plate, The Production Specification

T 0.5-1.0mm × W1000mm × L 2000-3500mm

T 1.0-5.0mm × W1000-1500mm × L 2000-3500mm

T 5.0- 30mm × W1000-2500mm × L 3000-6000mm

T 30- 80mm × W1000mm × L 2000mm

TC2 Titanium Alloy Aheet Plate, Production Status

Hot working state (R) Cold working state (Y) Annealing state (M)

TC2 Titanium Alloy Aheet Plate, Reference Standard

1: GB 228 Metal tensile test method

2: GB/T 3620.1 Titanium and titanium alloy grades and chemical composition

3: GB/T3620.2 Titanium and titanium alloy processed products chemical composition and composition allowable deviation

4: GB 4698 Sea surface method for chemical analysis of titanium, titanium and ferroalloys

TC2 Titanium Alloy Aheet Plate, The Technical Requirements

1: The chemical composition of titanium and titanium alloy plate shall comply with the provisions of GB/T 3620.1. In the case of reinspection, the allowable deviation of chemical composition shall comply with the provisions of GB/T 3620.2.

2: The allowable deviation of the thickness of the plate should comply with the provisions of Table 1.

3: The allowable deviation of plate width and length should comply with the provisions of Table 2.

4: The corners of the plate should be cut into right angles as far as possible. The deviation should not exceed the length and width of the sheet

Alloying

TC2 Titanium Alloy Aheet Plate,An alloy based on titanium with other elements added. There are two kinds of homogenous crystals in titanium: α titanium with dense hexagonal structure is below 882℃, and β titanium with body center cube is above 882℃.

(1) Alloying elements can be divided into three categories according to their effect on phase transition temperature:

α -stable elements, such as aluminum, carbon, oxygen and nitrogen, stabilize α phase and increase phase transition temperature. Aluminum is the main alloying element of titanium alloy, which has obvious effect on improving the strength of alloy at room temperature and high temperature, reducing the specific gravity and increasing the elastic modulus.

(2) β -stable elements can be divided into two types: isocrystalline and eutectoid. Products made of titanium alloy

The former has molybdenum, niobium, vanadium and so on; The latter has chromium, manganese, copper, iron, silicon and so on.

(3) The elements that have little effect on phase transition temperature are neutral elements, such as zirconium and tin.

Oxygen, nitrogen, carbon and hydrogen are the main impurities in titanium alloys. The solubility of oxygen and nitrogen in the α phase is greater, which has a significant strengthening effect on the titanium alloy, but decreases the plasticity. The content of oxygen and nitrogen in titanium is usually below 0.15 ~ 0.2% and 0.04 ~ 0.05%, respectively. Hydrogen has very little solubility in the α phase, and too much hydrogen dissolved in titanium alloys produces hydrides, which make the alloy brittle. Hydrogen content in titanium alloy is usually controlled below 0.015%. The dissolution of hydrogen in titanium is reversible and can be removed by vacuum annealing.

Chemical Composition

| Grade | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Tensile Strength

| Grade | Elongation(%) | Tensile Strength (Min) | Yield Strength (Min) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

Titanium And Alloy Products

| Product name | Specifications |

| Titanium Rod & Bar & Ingots | Ф3mm~Ф1020mm,the maximum weight is up to 12t |

| Titanium Slab | (80~400)mm×(~1500)mm×(~2600)mm |

| Titanium Forgings | Weight per piece≤2000kg |

| Titanium Hot-rolled plates | (4~100)mm×(800~2600)mm×(2000~12000)mm |

| Titanium Cold-rolled Sheet | (0.01~4.0)mm×(800~1560)mm×( ~6000) mm |

| Titanium Foil / Strips | (0.01~2.0)mm×(800~1560)mm×L |

| Titanium Tubes / Pipes | Ф(3~114)mm×( 0.2~5)mm × (~15000)mm |

| Standards | GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS,ГОСт |

| Titanium Grade |

|

Product Display