Well-designed Astm A53 Welded Steel Pipe - X60 Line Pipe – Zheyi

Well-designed Astm A53 Welded Steel Pipe - X60 Line Pipe – Zheyi Detail:

X60 Line Pipe, Standard

API SPEC 5L — American Petroleum Institute Standard

GB/T9711 — National standard of China

X60 Line Pipe, Mechanical Properties Of

X60 Line Pipe, Surface heat treatment is divided into two categories, one is chemical heat treatment, one is surface quenching and tempering heat treatment, the hardness test method is as follows:

[1] Chemical heat treatment of X60 pipeline

– Chemical heat treatment is to make the surface of X60 pipeline tube infiltrate one or several chemical element atoms, so as to change the chemical composition, structure and properties of X60 pipeline tube surface. After quenching and low temperature tempering, the surface of X60 pipeline pipe has high hardness, wear resistance and contact fatigue strength, and the core of X60 pipeline pipe has high strength and toughness.

– The main technical parameters of chemical heat treatment X60 pipeline are the depth of hardened layer and surface hardness. The depth of hardened layer should be tested by vickers hardness tester. Measure the distance from X60 pipe surface to the point where hardness drops to 50HRC. This is the effective depth of hardening chemical heat treatment of X60 pipeline tube surface hardness testing and surface hardening heat treatment the hardness of the X60 pipeline tube detection, can use vickers hardness tester, surface rockwell hardness tester or rockwell hardness tester to test, only the thickness of nitriding thick thin, generally not more than 0.7 mm, then can no longer use the rockwell hardness tester, Microhardness tester can be used.

[2] X60 pipeline surface quenching and tempering heat treatment

– Surface quenching and tempering heat treatment is usually carried out by induction heating or flame heating. The main technical parameters are surface hardness, local hardness and effective hardening layer depth. Vickers hardness tester can be used for hardness testing, rockwell or surface Rockwell hardness tester. The selection of test force (scale) is related to the depth of effective hardening layer and surface hardness of X60 pipeline. There are three kinds of hardness meters involved.

Vickers hardness tester is an important means to test the surface hardness of heat treated X60 pipeline pipe. It can use 0.5 ~ 100kg test force to test the surface hardening layer as thin as 0.05mm. Its accuracy is the highest, and it can distinguish the slight difference of surface hardness of heat treated X60 pipeline pipe. In addition, the depth of the effective hardening layer is also measured by vickers hardness tester, so it is necessary to equip a Vickers hardness tester for the units that carry out surface heat treatment or use a large number of surface heat treatment workpiece.

– Surface Rockwell hardness tester is also very suitable for testing the hardness of surface hardened X60 pipeline pipe. There are three scales for surface Rockwell hardness tester to choose from. Can test a variety of surface hardened X60 lines with effective hardening depth greater than 0.1mm. Although the precision of surface Rockwell hardness tester is not as high as vickers hardness tester, it can meet the requirements as a testing method for quality management and conformity inspection in heat treatment plants. Moreover, it also has the characteristics of simple operation, convenient use, low price, rapid measurement, and can directly read the hardness value, etc. Surface Rockwell hardness tester can be used for batch of surface heat treatment X60 pipeline pipe rapid and non-destructive testing. This is of great significance for X60 pipeline processing and machinery manufacturing plants.

– Rockwell hardness tester can also be used when the surface hardening layer is thick. When the thickness of hardened layer of heat treatment is 0.4 ~ 0.8mm, HRA scale can be used, when the thickness of hardened layer is more than 0.8mm, HRC scale can be used.

– Vickers, Rockwell and Surface Rockwell hardness values can be easily converted into standard, drawing or user required hardness values. Corresponding conversion tables are given in international standards ISO, American standard ASTM and Chinese standard GB/T.

[3] Local heat treatment

– If the local hardness of parts is required to be high, local quenching heat treatment can be carried out by induction heating and other methods. Such X60 pipeline pipes usually need to mark the location of local quenching heat treatment and local hardness value on the drawing. Hardness testing of X60 pipe shall be carried out in the designated area. Hardness testing instrument can use Rockwell hardness tester, test HRC hardness value, such as heat treatment hardening layer is shallow, can use surface Rockwell hardness tester, test HRN hardness value.

Chemical Composition

| Standard | Brand | Chemical composition (%) | CEV(%) | ||||||

| C | Si | Mn | P | S | V | Ti | |||

|

API SPEC 5L GB/T9711.2 |

B | ≤0.16 | ≤0.40 | ≤1.10 | ≤0.020 | - | - | - | ≤0.42 |

| X42 | ≤0.17 | ≤0.40 | ≤1.20 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.04 | ≤0.42 | |

| X52 | ≤0.20 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.04 | ≤0.45 | |

| X60 | ≤0.21 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.04 | 协议 | |

| X65 | ≤0.16 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.06 | ≤0.45 | |

| X70 | ≤0.16 | ≤0.45 | ≤1.70 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.06 | ≤0.45 |

Note:

1.0.015% Altot< or less; 0.06%; N 0.012% or less; Al/N 2/1 or higher; Cu 0.25% or less. Ni 0.30% or less. Cr 0.30% or less; Mo 0.10% or less

2. V + Nb, Ti 0.15 or less

3. Mo≤0.35% for X60, X65 and X70 after negotiation

| Standard | Brand | Tensile strength(MPa) | The yield strength(MPa) | showed | Percentage of elongation (%) |

0 ℃ impact energy Akv (J)

|

Heat treatment condition |

|

API SPEC 5L GB/T9711.2 |

B | ≥415 | 245~440 | ≤0.80 | 22 | ≥40 | Is the fire |

| X42 | ≥415 | 290~440 | ≤0.80 | 21 | ≥40 | Is the fire | |

| X52 | ≥460 | 360~510 | ≤0.85 | 20 | ≥40 | Is the fire | |

| X60 | ≥520 | 415~565 | ≤0.85 | 18 | ≥40 | Is the fire | |

| X65 | ≥535 | 450~570 | ≤0.90 | 18 | ≥40 | Quenching + tempering | |

| X70 | ≥570 | 485~605 | ≤0.90 | 18 | ≥40 | Quenching + tempering |

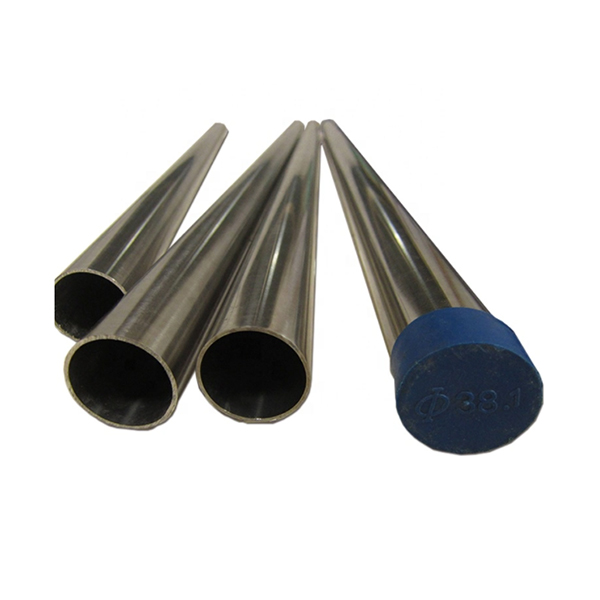

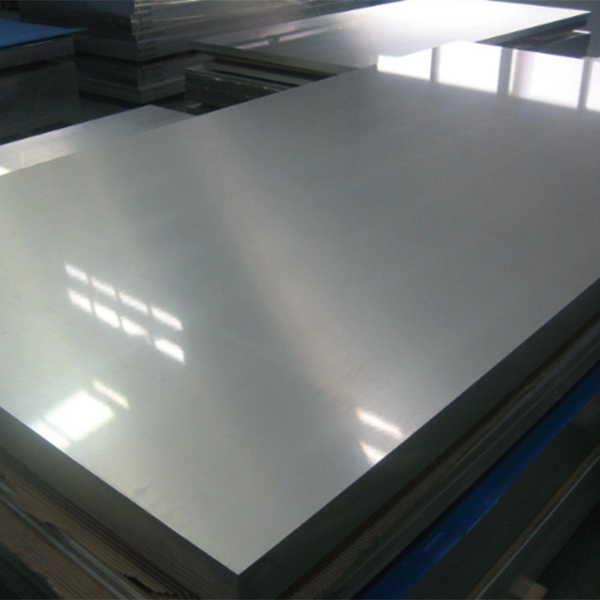

Product Display

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for Well-designed Astm A53 Welded Steel Pipe - X60 Line Pipe – Zheyi , The product will supply to all over the world, such as: Kazakhstan, Poland, Kyrgyzstan, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!