a106 gr c seamless steel pipe

a106 gr c seamless steel pipe,Divided into hot rolled and cold rolled (dial) seamless steel tube two types. Hot rolled seamless steel tubes are classified into general steel tubes, low and medium pressure boiler tubes, high pressure boiler tubes, alloy steel tubes, stainless steel tubes, petroleum cracking tubes, geological tubes and other steel tubes. Cold rolled (dial) seamless steel pipe in addition to general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipe, also includes carbon thin-walled steel pipe, alloy thin-walled steel pipe, stainless steel pipe, special-shaped steel pipe. The outer diameter of hot-rolled seamless pipe is generally greater than 32mm, and the wall thickness is 2.5-75mm. The outer diameter of cold-rolled seamless steel pipe can reach 6mm, and the wall thickness can reach 0.25mm. The outer diameter of thin-walled pipe can reach 5mm and the wall thickness is less than 0.25mm.

a106 gr c seamless steel pipe,It is made of 10#, 20#, 30#, 35#, 45# and other high-quality carbon bonded steel 16Mn, 5MnV and other low alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other bonded steel hot rolled or cold rolled. 10#, 20# and other low carbon steel manufacturing seamless pipe is mainly used for fluid pipeline. 45, 40Cr and other medium carbon steel made of seamless pipe to manufacture mechanical parts, such as cars, tractors stressed parts. The general use of seamless steel pipe to ensure the strength and flattening test. Hot rolled steel pipes are delivered in hot rolled or heat treated condition. Cold rolled delivery is heat - treated.

Hot rolled seamless steel pipe, as the name implies, the rolling temperature is high, so the deformation resistance is small, can achieve large deformation. Taking steel plate rolling as an example, the thickness of continuous casting billet is about 230mm, and after rough rolling and finishing rolling, the final thickness is 1~20mm. At the same time, because the thickness ratio of the steel plate is small, the dimensional accuracy is relatively low, it is not easy to appear the shape problem, mainly to control the crown. The microstructure and mechanical properties of strip steel can be controlled by controlling rolling temperature, rolling temperature and crimping temperature.

a106 gr c seamless steel pipe,It is a seamless steel pipe for conveying water, oil, gas and other high temperature fluids.

A106 GR C Seamless Steel Pipe, Execution Standard

ASTM A106-ASME SA106 is used for conveying water, oil, gas and other high temperature fluids. A106A, A106B, A106C a106gr.b.

A106 GR C Seamless Steel Pipe, Mechanical Properties Of

| Standard for seamless steel tube | Steel grades | Tensile strength (MPA) | Yield strength (MPA) |

| ASTM A106 | A | ≥330 | ≥205 |

| B | ≥415 | ≥240 | |

| C | ≥485 | ≥275 |

Specification

| O.D. | NPS 1/4" to 30" |

| W.T. | Sch 10 through 160, STD, XS, XXS |

| Length | SRL, DRL or Custom |

Standard & Grade

| Standard | ASTM A106, ASME SA106 |

| Steel grade | Gr.A, Gr.B, Gr.C |

Other Details

| Process | hot finished, cold drawn |

| Name of material | seamless |

| Painting & Coating | oilded, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating, Anti rust oil, 3LPE,3LPP,FBE etc |

| Ends | Plain ends, Beveled ends |

| Delivery | Depends on the order quantity, normal within 30 days |

| Payment | T/T, L/C, Western Union |

| Packing | Bundled, In Bulk, Plastic caps plugged, Waterproof paper wrapped etc. |

| Application | Chemical, Oil and Gas transmission, Subsea pipelines, offshore, Underground, Petroleum, Marine Engineering, Electricity, Coal transportation, Municipal engineering and textile, Paper etc. |

| Tests of LSAW steel pipe | Chemical Component Analysis; Mechanical Properties--Elongation, Yield Strength, Ultimate tensile strength; Technical Properties--DWT Test, Impact Test, Blow Test, Flattening Test X-ray Test Exterior size inspection Hydrostatic test UT Test |

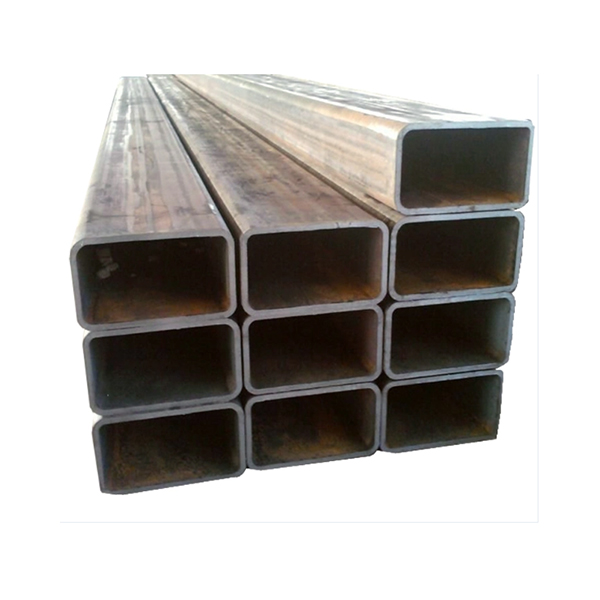

Product Display